Sustainable Buildings and Construction

Background Information on Sustainable Buildings and Construction

With the population of the world growing, global warming, the world’s frightening dependence on oil, the issue of energy is concerning and some people are easing this concern. One way that people have been trying to help the Earth is by “Green Building.” This is different from traditional building in that builders are now paying attention to eco-friendly materials, zero-carbon emission buildings, net-zero energy buildings, and “off the grid” buildings. Green building is an alternative way of construction that aims to build sustainable and eco-friendly buildings. Some of this technology has been around for some time, but it is finally starting to catch the eye of more and more people and businesses.

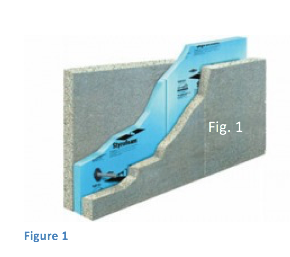

The company that our group decided to investigate was Living Earth Construction. Living Earth Construction (LEC) was started by John Andrews in 1992 and has succeeded in the green building industry. The focus of LEC was to build sustainable, off-the grid homes for a lower cost. The homes that John has built are commonly called earthships. These earthships are built out of nearly all recycled materials and are commonly insulated by straw. These homes are designed to tap into the thermal energy of the Earth, by being burmed into the Earth on three sides. The fourth side is the south side; comprised entirely of windows to create light and heat from the sun. Solar panels are also placed on the roof to absorb energy from the sun. To make the homes completely sustainable, they have catch water and grey water systems to catch precipitation and to clean the water. The advantage of these homes is that the construction cost is lower and the energy costs are minimal, if still on the grid. John himself lives in one of these homes. While John has mastered this trade, the components of these earthships are generally standard. Since the demand for these homes is not high, John decided to take his knowledge in the green building industry and refine it. John decided to team up with fellow green builder, Steve Kroll, and create a company called Corvid Construction. Corvid has patented a radiant wall system, which is an improvement of the industry known SIP (Figure 1).

A SIP is a structural insulated panel which is a structural wall with foam cores. These are much more energy efficient than stick buildings and stand up concrete buildings by up to 60%. The reason they are more energy efficient is because they have continuous tight insulation throughout the entire wall and the construction of the building requires less joints to be sealed, which is where most air leaks. There are other advantages to using SIPs besides energy reduction. One advantage is lowered construction costs. In a school built in Las Vegas, construction costs were reduced by $2 million due to the 60% reduction in time it took to frame the school and the two-thirds reduction in the amount of waste produced during construction. Another advantage is that SIPs promote healthier indoor air quality. The tightness of the building allows for less harmful material to be introduced to the building. There are many advantages to using these structural insulated walls and if used in conjunction with other green building techniques, the industry can start to set new standards (Hodgson, 2010).

After contacting John and finding out that Living Earth was not his main focus anymore, we were relieved to hear that he had started something newer and innovative: Corvid Incorporated. He told us that he had had just finished a project with Corvid and that we should come check out the net-zero energy fire house he had just built in Alice, Colorado.

A net-zero energy building is a building that produces as much energy as it uses. This means that it uses minimal energy for heating, cooling, and electricity. This is achieved by using SIPs, geothermal principles, and special windows and doors. The building must also produce its own energy which is usually achieved by active or passive solar systems. These buildings are showing up in remote locations and are starting to take hold of larger entities as well. The state of California has created an energy plan which includes net-zero energy construction for commercial buildings by 2030 and for residential buildings by 2020. The new energy plan includes developing financial tools for supporting net-zero energy and supporting integrated design for new construction (Wendt, 2010). By using the net-zero energy building techniques and systems, including the “Corvid radiant wall system,” the successful construction of the net-zero energy firehouse was achieved.

Project Description

This firehouse was the project that we visited and investigated to gain an insight to the green building industry (Figure 2). This was a good project to learn from because it involves the specific patented wall system along with other standard green building systems. Firehouse Station No. 7 is owned by the Clear Creek Fire Authority and is located in Alice, Colorado, which is known for nearby St. Mary’s Glacier. This building is 4,200 square feet, which being a firehouse, includes a large garage, an office, two bedrooms, a main room, a maintenance room, and a kitchen. The estimated cost of construction was about $150/square foot which is $630,000 total for the building. For a building with a sophisticated energy system, this seems to be a very attractive number. Corvid Construction was the general contractor and Tom Peterson was the architect. Corvid has also teamed up with Franklin’s Tower and Associates who did the subcontracting of the building. Although this winter seems to be mild, Corvid is confident that the building will pass the test for many winters to come at 10,000 feet.

Sustainable Building Components

The Clear Creek Fire Authority station in Alice incorporated only a few sustainable components into the building, but all of these components were extremely important in making the building meet its net-zero energy goal. When talking about a net-zero energy building, it means that the building does not rely on the power grid to supply its energy. A net-zero energy building harvests its own energy onsite which is then used to supply power to the building, and also can supply energy back into the power grid. With this principle in mind, this building used four components to achieve net-zero energy. These components were the Corvid Radiant Wall System, flat-plate collectors, geothermal heat pumps, and photovoltaic solar system.

The main component of the whole building system was the Corvid Radiant Wall System which is a combination of a SIP and a radiant floor system. This patented system was created by John Andrews and Steven Kroll of Corvid Incorporated. Basically, the system is just like a radiant floor system, which has been used for many years, but is turned on its side to be used vertically. The wall consists of 4 inches of exterior concrete, 3 inches of THERMOMASS® Dow Styrofoam insulation, and 6 inches of interior heated or cooled concrete (Corvid Incorporated, 2008). Before the interior concrete layer is poured radiant tubes are placed throughout the entire wall. After the construction of the wall is complete, hot or cold water is pumped through the radiant tubes to control the temperature of the building (Figure 3). By pumping water through the walls this system incorporates another element to a SIP and as a result performs better. This system works so well because the water transfers its energy properties to the interior concrete which acts as thermal mass for the building. Since the interior thermal mass is insulated from the exterior concrete by the insulation, the interior walls can continue to radiate heat in the winter time and absorb heat in the summer time. The system also includes a radiant floor system to utilize the area of the floor for thermal mass as well. By using this system, the need for a furnace, any baseboard heaters, or even air conditioners is eliminated, which dramatically reduces the energy costs for a building. All of the tubes run into one maintenance room where each wall zone is controlled by a valve (Figure 4). The water source for the walls can either come from the cold water source or the hot water heater. Although, the water pumped through the walls can come from the water heater, which requires the gas burner to turn on, the other sustainable components supply most of the hot water, so the burner does not turn on that often.

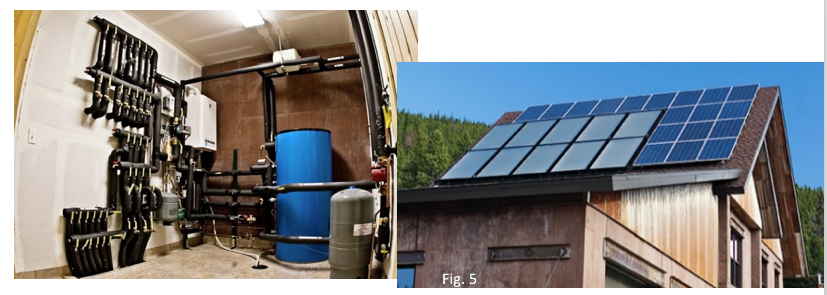

To supply most of the hot water for the radiant wall system, 10 flat-plate collectors were installed on the roof (bottom left panels in Figure 5).

To supply most of the hot water for the radiant wall system, 10 flat-plate collectors were installed on the roof (bottom left panels in Figure 5). The flat-plate collectors capture radiant heat from the sun and transfer that heat to a glycol liquid which is then pumped into the hot water heater to exchange the heat to the water. Glycol instead of water was used because the glycol doesn’t freeze in cold weather. In addition to the flat-plate collectors a geothermal pump is installed to provide additional heat. The geothermal pump runs tubes through the ground, and the glycol liquid is pumped through to capture heat from the earth. Generally the ground can maintain a temperature of 50 degrees or more, depending on how deep the tubes are run (Andrew, 2010). So, by capturing this heat and using a basic refrigeration cycle, the water heater receives additional heat. Although this was not used for this building, the geothermal pumps can also be used keep the building colder in the summer time by using the colder earth temperature.

The final sustainable components that were installed were the photovoltaic solar panels or PV panels. On the roof, 18 panels were installed to provide electricity for the building (upper right panels in Figure 5). The electricity gained from these panels was used to supply power to all the pumps used for the wall system, as well as the pumps for the geothermal pump and the flat-plate collectors. However, these pumps did not use that much energy. The main use of the electricity was for the refrigerator in the kitchen (Andrew, 2010).

Each of these components alone can make a regular building a sustainable building, but all together they make the building an example for supreme efficiency. The flat-plate collectors and the geothermal pump provide the source of hot water, the radiant wall system distributes the hot water throughout the building’s interior concrete walls, and the PV panels provide the electricity for the whole building. In the end, the final product worked very well. When we went and visited the building on October 30, 2010, we were able to witness how well it performed. The building maintained a constant temperature of 65 degrees Fahrenheit , even after it was cloudy for 4 days and the outdoor temperature got down to 18 degrees Fahrenheit (Andrew, 2010). Also, during this time the gas burner in the hot water heater was never turned on. The PV panels were still working well and were providing more than enough energy for the building because the building was actually pumping energy back into the power grid. Considering all these factors and the fact that the building was located in Alice, Colorado, which is at 10,079 feet above sea level, this building performed incredibly well. Because of how well the fire stationed worked, this type of building should continue to be constructed in cold and even in warm climates.

Some may wonder what the “catch” is and why this technology is not used everywhere. The truth is there are some things that are compromised. First of all, the upfront cost may be a little more than the generic building because the PV panels, flat-plate collectors, and pumps may cost a little more. However, in the long run this building will make utility costs go close to zero, and will earn money with the PV panels. People just have to be willing to pay this initial cost. Also, anytime there is work being done on roofs, for example installing solar panels, the installation can be dangerous which may turn people away. One main potential issue is in the case that one of the radiant tubes starts to leak. Since the tubes are surrounded by concrete, it is practically impossible to fix the leak without redoing the entire wall. But, if this happens, the zone with the leak can be turned off and can act as a normal SIP without the radiant tubes. Also, a leak would not be that serious and would probably go unnoticed because the concrete would prevent the water from leaking out. One issue that may be important to some people is aesthetics, since concrete alone can be displeasing. But in the building we observed, the concrete was stained a nice color, and if needed the interior concrete could be covered up with many different types of materials.

Even though there are a few things that may be compromised, in the end, the efficiency of the building outweighs the problems. The main issue is showing people the advantages of this technology. Even though radiant floor systems have been around for a long time, the Corvid Radiant Wall System is very new and this fire station is the first completed project. The Clear Creek Fire Authority decided to use this system because they wanted to make a new green station to save money on heating and decided to hire the local company Corvid Incorporated to help them with this task. Corvid decided to try out this system and because of its success they have now started on two new projects in the Denver area. Hopefully, this technology continues to grow and provide a new solution to making buildings as efficient as possible.

Challenges

With any design for any building there are going to be setbacks and challenges that a company must overcome. Corvid faces a very unique set of challenges.

Corvid, one could say, lives and dies by the sword when it comes to winning jobs, better yet to even be considered for a project. When it comes to “Green” building, there is an underlying preconception that to be environmentally responsible, it’s going to cost a pretty penny. For most cases this is true, but with Corvid Construction they have managed to be sensible both environmentally and economically. However labeled by green construction, Corvid does not even get the chance to show their sensibility. On the other-hand Corvid’s innovative net-zero wall design, has gotten them noticed, and singlehandedly won them jobs.

The preconception mentioned earlier was a large factor in John’s transition from the Living Earth Construction to Corvid. A lack in demand for passive solar encouraged John to explore new means of sustainable home building: i.e. Corvid Wall.

Because Corvid Wall is such a unique and innovative design the construction methods for achieving the product are still being perfected. One of the most hampering problems Corvid had when installing their product at Fire Station 7 was pouring the interior concrete. For their first pour they had a concrete mixture that had a very large slump factor. This slump caused the wall to harden with very noticeable wave marks (Figure 6)

A slight alteration with the formula corrected the slump and the rest of the pour hardened seamlessly.

When we visited Fire Station 7, and the Corvid Radiant Wall design was completely explained, we pondered what would happen if one of the tubes running through the wall were to rupture. John explained to us that the tubes were rated for 100 years, meaning no failures were to be warranted within a hundred years of installation. However, on the off chance that one of the tubes did rupture, the system is set up to have different faces and levels of the walls circulating independently of one another. With it independently circulated, a single section of wall can be shut off and flushed in the boiler room (fig.2) while the system continues to function.

Another issued faced by Corvid, is finding subcontractors that are willing and able to install the design. John and Steve’s past experience in the industry allowed them to make a connection with Franklin’s Tower and Associates, a local concrete subcontractor. Having this mutual relationship with Franklin ensures they will always have a contractor capable of delivering their product. In spite of this relationship, Corvid has a very fixed price for delivering their product, which can hamper their ability to bid competitively.

Looking at the maintenance room for Station 7 (Figure 4), it is obvious that Corvid Wall is a very intricate design. The complexity to the design leads us to believe that there is a ceiling for how large of a building Corvid Wall could be successfully implemented into. With that said, with Corvid Wall spearheading Corvid Construction’s campaign in Green construction we believe, despite said setbacks, Corvid Construction is on the cutting edge of green technology and construction. We hope that Corvid is able to persevere through the economic decline and make a serious splash in the industry.

Evaluation of Alternatives

The Clear Creek Firehouse is very efficient and self-sustained using active solar energy, however, there are numerous other ways the structure could be more environmentally friendly. The firehouse uses two different types of solar panels that convert solar energy into electrical power which results in the heating of the Radiant Walls. There are alternatives to heating the house other than using active solar energy, including various forms of passive solar energy.

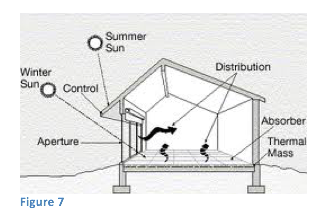

A passive solar heating system is integrated into the buildings elements (e.g. windows) and materials (e.g. tile-covered concrete floors) and does not rely on mechanical equipment to collect, store and distribute thermal energy from the sun (Wujek, 363). The objective of this method of heating a building is capturing the thermal energy within the building and releasing it throughout the structure when the sun is not shinning to provide heat. If accomplished, passive energy doesn’t emit greenhouse gases, has low maintenance, and no operating costs. The most important aspects of the system are the absorber (the darkened surface of the storage element that sits in the pathway of the sun), the thermal mass (the material that stores the heat from the sun-material behind the absorber), the distribution (method by which the heat is transported throughout the house), and control (naturally manages the heat intake to the structure-e.g. blinds or roof awnings to block summer sun).

The first option for a passive solar heating system is direct and indirect gain. The direct gain method uses the open space in the house as the absorber, and heat distribution system (Figure 7).

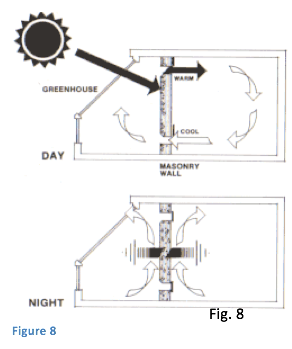

The windows in a house that uses direct gain are facing south to allow an adequate enough sunlight in during the winter, while denying sun access in the summer. The floors and walls act as the thermal masses, storing and providing heat to the rest of the house. With indirect gain, the solar energy passes through the glass of the house directly into a thermal storage wall, where it is stored. It then heats the house through convection of the thermal heart through the storage wall (Figure 8).

The figure shown displays a drawing of a “trombe wall,” which is one form of a thermal storage wall in which the ventilation allows the room air to flow through the openings by natural convection. The air is heated by the sun and then passed back through the upper vent to recirculate throughout the house. At night (or on an overcast day), the wall will release the thermal energy that was absorbed to heat the structure. Another option for indirect gain is a roof pond system. The system incubuses exactly what is sounds like by implementing a pond on the roof of a building to absorb thermal energy from the sun. When the water is heated from the sun, insulated panels can be placed over the pond. The heated water will then pass thermal energy to the house until the temperature of the water equilibrates to the temperature of its surroundings.

These ideas were turned down by the project design engineers for several reasons. When using a passive solar heating system, the climate and environment in which the building will be placed play a major factor. In most cases passive thermal heating systems are implemented in mild climates where weather does not reach the extremes in either summer or winter. The biggest deterrent for the engineers to use some of these methods was the fact that the firehouse was constructed in Alice. The mountainous town observes extreme weather in both summer and especially winter. They required more reliable methods of heating the fire house in order for them to be completely self-sustained (and not have to resort to outside sources for heating). In order to accomplish this an active solar heating system was required. Unlike a passive system, an active solar heating system can store solar thermal energy for a much longer period of time. A passive system is too reliant on the availability of the sun on a daily basis, and it is difficult to find ways to sustain this energy unless you have solar panels that can store, and convert solar thermal energy into electricity (which in turn power the houses heating and other electrical needs).

There was a lot that we, as a group, were able to take away from the implementation of the sustainability of the Clear Creek Firehouse. It demonstrated the innovation that can be used as alternative sources of energy to power a normal household. It also taught us to think outside the box to develop new concepts for construction. The engineers on the project developed the radiant wall system by using the same concept as a radiant floor and applying it to the ceiling and walls. It is a very simple idea, but innovative because no one else had thought to try the concept. The whole project has been a very enlightening experience and has furthered our knowledge and interest in the construction industry.

Works Cited

Andrew, J. (2010, 10 30). Mr. (G. 10, Interviewer)

Corvid Incorporated. (2008). About the Wall. Retrieved December 2010, from Corvid Radiant Wall System: http://corvidwall.com

Hodgson, J. (2010, May 24). A Starting Point for Net_Zero Energy Buildings. Retrieved December 6, 2010, from ECO-Structure: http://www.eco-structure.com/energy-efficiency/a-starting-point-for-net-zero-energy-buildings.aspx

Wendt, A. (2010, October 1). California Takes Concrete Steps Toward Net-Zero-Energy Buildings. Retrieved December 7, 2010, from Environmental Building News: http://www.buildinggreen.com/auth/article.cfm/2010/9/29/California-Takes-Concrete-Steps-Toward-Net-Zero-Energy-Buildings/

Wujek, Joseph B. Mechanical and Electrical Systems in Architecture, Engineering, and Construction. Fifth ed. Upper Saddle River, New Jersey: Pearson Prentice Hall, 2010.